● Position / speed / torque control mode;

● Mixed control mode: position / speed, speed / torque, position /torque control mode;

● Command source selection: internal / external position command,internal / analog speed command; internal/analog torque command.

● Analog torque limit / analog speed limit

● Multiple sets of electronic gear ratios are switched.

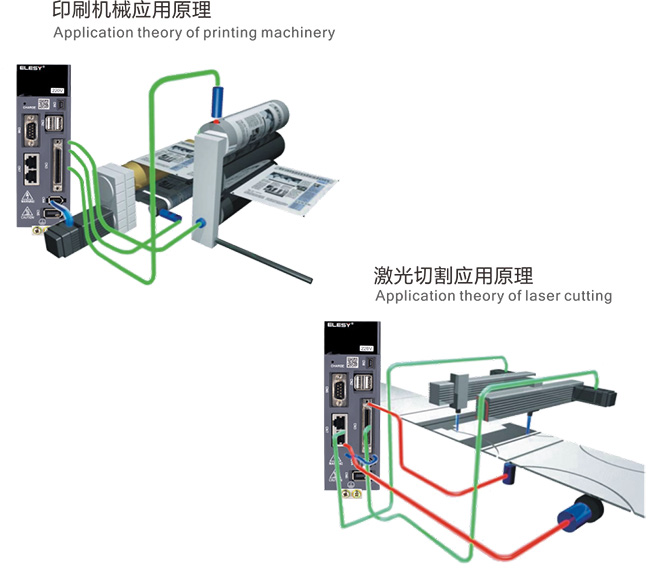

● Examples of application: feeder, film splitter, coiler, packaging machinery,printing machinery, embroidery machinery, winding machine and lasercutting machinery.

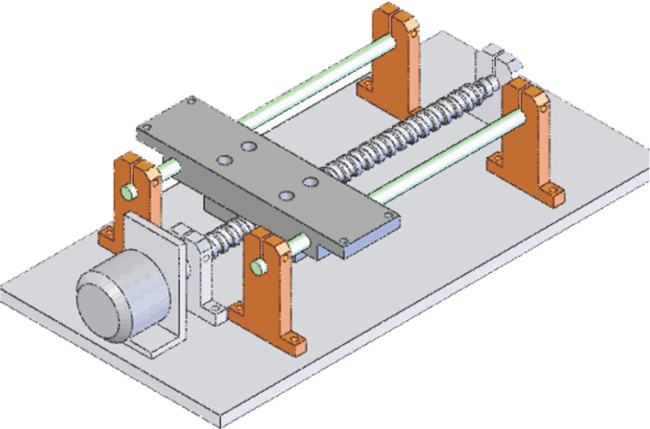

● To support external encoder and grating scale (A, B,Z format)

● To reduce the impact of mechanical slipping and transmission back clearance and ensure the positioning accuracy of mechanical terminals

● Examples of application: CNC machine tools, feeding machine, etc.

● Multiple sets of gain selection and gain switching function

● Position feed forward and speed feed forward function can significantly reduce tracking error.

● Load inertia ratio setting, online identification function and simplified gain adjustment.

● The wave trap function eliminates vibration and abnormal noise caused by mechanical resonance.

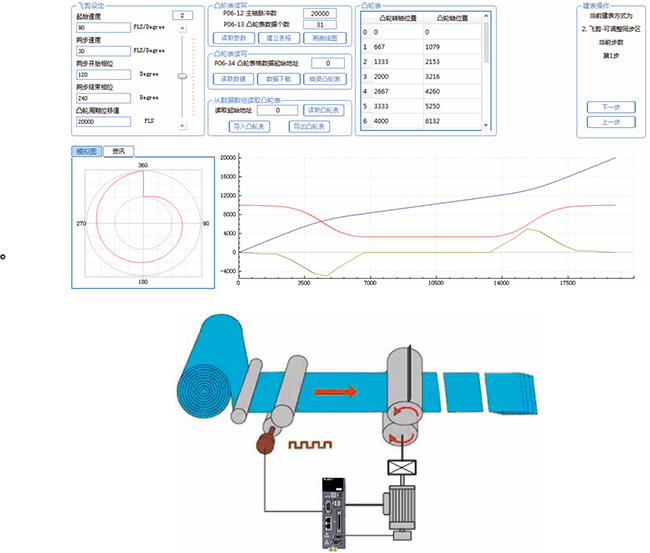

● The cam curve data can reach 720 points.

● The cubic curve is interpolated by software between two adjacent points,and the number of points does not affect the smoothness of the operation.

● To support flying shear, chasing shear and customize curve planning

● Easy to use ELESY Soft software to make planning and setting

● The driver has the macros for built-in flying shear and chasing shear to directly adjust and re-plan the curve.

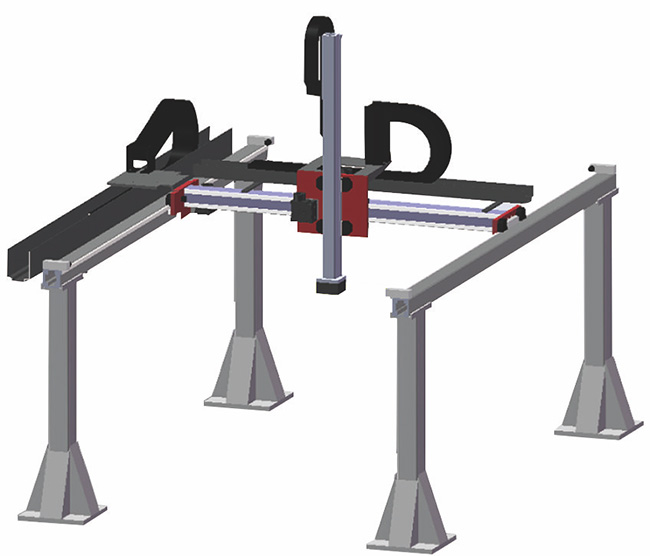

● The gantry-type mechanism can be driven by double shaft and the driver can synchronize its position automatically.

● When the deviation of synchronized position exceeds the set value, the driver will give an alarm and stop running.

● The servo system computer sends pulse commands to two drivers simultaneously.

● Via cross connection of position feedback pulse signals from two drivers, the motor running speed is adjusted in real time to synchronize the positions of two shafts.

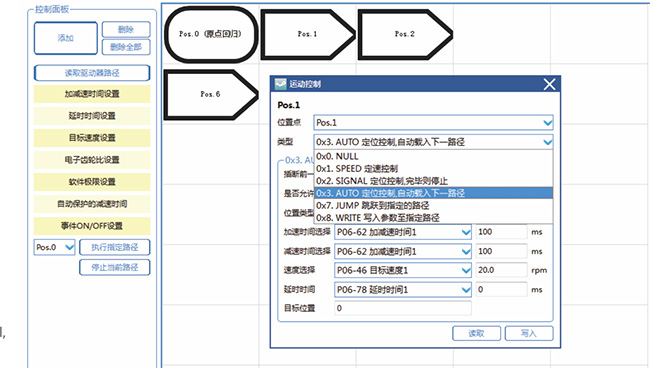

● To provide a 32-segment path for the user to make the planning flexible.

● Route types include: zero return, constant speed control, positioning control,modification parameters, and jump path.

● Position control support: absolute positioning, relative positioning,incremental positioning, CAP capture positioning.

● Multi-stage acceleration /deceleration time, delay time and target speedare optional.

● It is convenient to use with the adoption of position control

● Multiple trigger modes: software trigger, CNTR signal trigger,EV1/2/3/4 event trigger (jump edge optional).

● The graphical setting operation is made via ELESY Soft software and easy for setup.

● With the built-in RS-485 interface, support MODBUS communication protocol.

● To support MECHATROLINK- II / III bus communication protocol.

● To support CANopen bus communication protocol, support CiA-301,DSP-402 sub-protocol.

● To support EtherCAT bus communication and IEC61800-7(CZA402)-CANopenmotion control sub-protocol is adopted for the application layer.

● With the corresponding servo system controller,such as CNC numerical

control system, PLC, controller, etc., multiple servo drivers can be networked.

● To support communications with the driver through RS-485 or USB;plug and play, easy to connect.

● The parameter editor allows the user to view the modified servo parametersin real time and provide and provide information such as parameter descriptionand setting range; import support and export the user parameter tables, whichcan conveniently configure servo drivers in batches.

● The oscilloscope supports 4-channel data acquisition with a refresh rate of 1 kHz,

● The user can monitor the servo running waveform, to scale, measure, import, andexport the waveform data.

● The IO controller can directly select terminal logic and the function to look at thestatus of the terminals in real time.

● Graphical settings is used for motion control and electronic cam function.

● Easy to configure and debug related functions.

● In addition, it also provides functions such as gain adjustment, parametermonitoring and alarm information.

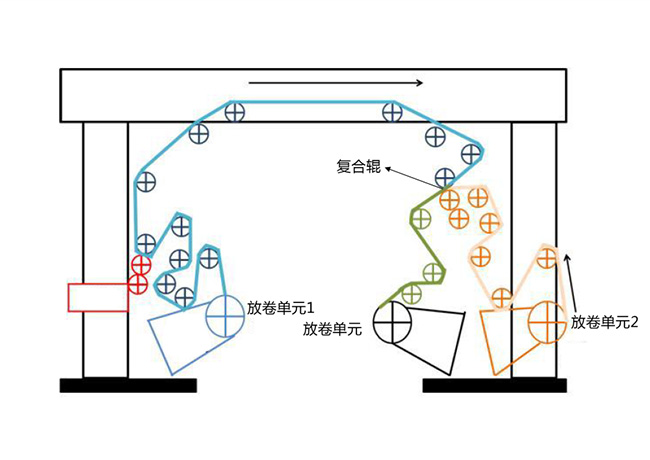

● The driver can share the DC bus and the energy is fully utilizedso that the device is more energy- efficient;

● To reduce the quantity of braking resistors,power requirementsand the cost of accessories.

● Cases of Application: printing equipment, textile equipmentand unwinder / rewinder

Wechat

QR Code